Chain Surveying- Definition & Principle

Chain Surveying- Definition & Principle

|

| Chain Surveying |

Definition

Chain surveying is the art of determining the relative positions of different objects on the surface of the earth by measuring the horizontal distance between them, and by preparing a map to any suitable scale. The measurement is taken in the horizontal plane.

Principle

The principal triangulation. This means that the area to be surveyed is divided into many small triangles that should be well-conditioned.

Read More: Surveying- Definition and Classification

Chain surveying is recommended when

(1) The ground surface is more or less level.

(2) A small area is to be surveyed.

(3) A small-scale map is to be prepared.

(4) The formation of well-conditioned triangles is easy.

Chain surveying is unsuitable when

(1) The area is crowded when many details.

(2) The area consists of too many undulations.

(3) The area is very large.

(4) The formation of well-conditioned triangles becomes difficult due to obstacles.

|

| Chain |

Equipment For Chain Survey

The following equipment are required for conducting chain surveys:

(1) Metric chain(20m) = 1no

(2) Arrows = 10no.

(3) Metallic tape(15m) = 1 no.

(4) Ranging rod = 3no.

(5) Offset rods = 1 no.

(6) Clinometer = 1 no.

(7) Plumb bob with thread = 1no.

(8) Cross staff or optical square = 1 no.

(9) Prismatic compass with stand = 1 no.

(10) Wooden pegs = 10 no.

(11) Mallet = 1no.

(12) Field book = 1 no.

(13) Good pencil = 1 no.

(14) Pen knife = 1no.

(15) Eraser = 1no.

|

| Chain Surveying |

Definitions And Illustrations

(A) Survey stations are the points at the beginning and the end of a chain line. They may also occur at any convenient points on the chain line.

Such stations maybe

(1) Main Stations

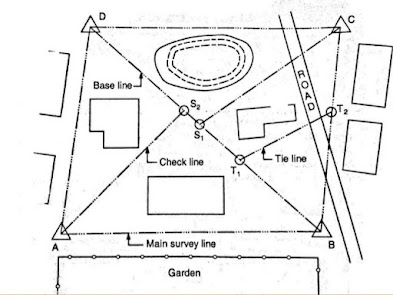

Stations taken along the boundary of an area as controlling points are known as main stations. The lines joining the main stations are called main survey lines. The main survey lines should cover the whole area to be surveyed. The main stations are denoted by’∆’ with letters A, B, C, D, etc.

(2) Subsidiary Stations

Stations that are on the main survey lines or any other survey lines are known as subsidiary stations. These stations are taken to run subsidiary lines for dividing the area into triangles, for checking the accuracy of triangles, and for locating interior details. These stations are denoted by ‘◎’ with letters S1, S2, S3, etc.

(3) Tie Stations

These are also subsidiary stations taken on the main survey lines. Lines joining the tie stations are known as tie lines. Tie lines are mainly taken to fix the directions of adjacent sides of the chain survey map. These are also taken to from chain angles in chain traversing when triangulation is not possible. Sometimes tie lines are taken to located interior details. Tie stations are denoted by ‘◎’ with letters T1, T2, T3, etc.

(B) Base Line

The line on which the framework of the survey is built is known as the baseline. It is the most important line of the survey. Generally, the longest of the main survey lines is considered the baseline. This line should be taken through the fairly level ground and should be measured very carefully and accurately. The magnetic bearings of the baseline were taken to fix the north line of the map.

(C) Check Line

The line joining the apex point of a triangle to some fixed point on its base is known as the check line. It is taken to check the accuracy of the triangle. Sometimes this line helps to located interior details.

(D) Offset

The lateral measurement taken from an object to the chain line is known as an offset. Offsets are taken to located objects concerning the chain line.

They may be of two kinds - Perpendicular and Oblique.

1. Perpendicular Offsets

When the lateral measurements are taken perpendicular to the chain line, they are known as perpendicular offsets.

2. Oblique Offsets

Any offset not perpendicular to the chain line is said to be oblique. Oblique offsets are taken when the objects are at a long distance from the chain line or when it is possible to set up a right angle due to some difficulties. Such offsets are taken in the following manner.

|

| Surveying |

Sources Of Errors In Chain Surveying

i. Incorrect holding of the chain.

ii. Errors in measurement of right angles with chain.

iii. The length of the chain is shorter than the standard length.

iv. Sag in the chain.

v. Elongation of the links due to heavy pull.

vi. The temperature during measurement being much higher than the standard temperature.

vii. Variable tension in the chain.

viii. Chain getting out of line due to wrong ranging.

ix. While making entries in the field book, figures may be interchanged due to carelessness.

No comments

Thank You For Your Comment.